HDD drilling truck with PTO driven mix pump set

A horizontal directional drilling project which is arranged from A to Z requires a lot of professional equipment. Therefore, it is very useful to be able to move as much as possible at once in, for example, an HDD drilling truck. The compact mix pump set in the drilling truck designed by Bofram offers the perfect solution.

From beer truck to drilling truck

3D-Drilling had bought a truck that was used to transport beer. This truck was equipped with roller blinds and Bofram converted it from a beer wagon to a drilling vehicle. First, we removed the tarpaulins and installed plywood sidewalls. In addition, a door with steps was placed on the right-hand side of the truck so the operator of the mix pump set can easily get in and out of the truck. In the back of the truck, extra driving plates have been mounted so the drill rig can be easily driven into the drilling truck. Because the Bofram mix pump set is so compact, there is enough space for this.

The HDD system

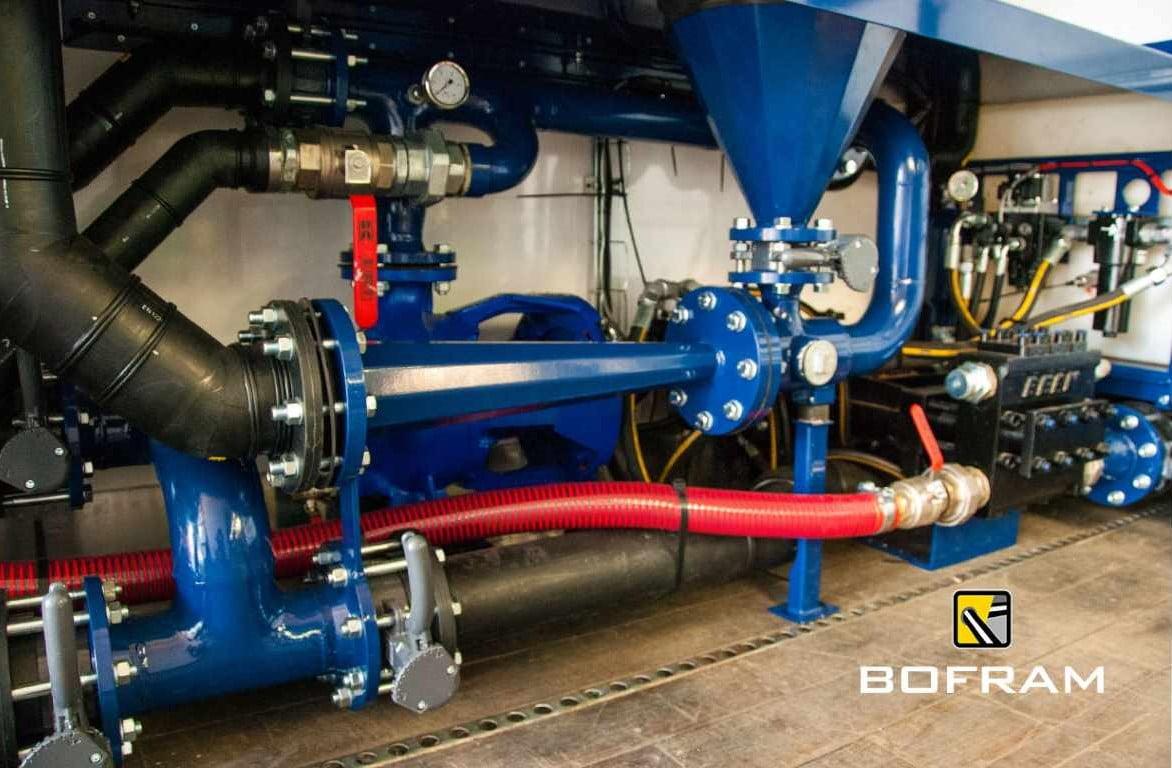

Under the truck, we have placed a diesel and oil tank for the double PTO. Two high-efficiency hydraulic pumps are mounted on the PTO’s to drive the mixing pump, high-pressure pump, hose reel, high-pressure bentonite pump, and hydro motors. An EXTRA diesel tank with a pump has also been mounted. This allows the drilling machine to be refueled and avoids the drillers having to carry jerrycans.

There are three tanks in the truck: a 5 m3 storage tank, a 1.5 m3 mixing tank, and a 1.5 m3 water tank. The tanks contain nozzles for optimum mix capacity and speed. The pipework to and from the tank has sufficient butterfly valves to generate various flushing directions. The clean water pipe is fitted with a wastewater filter. The filling pipe for bentonite liquid to the machine is located in the back of the truck. The tanks have small stairs to easily look in the tank, a manhole, and a drainage point at the bottom of the tank. Underneath the 1.5 m3 tanks, there are material compartments.

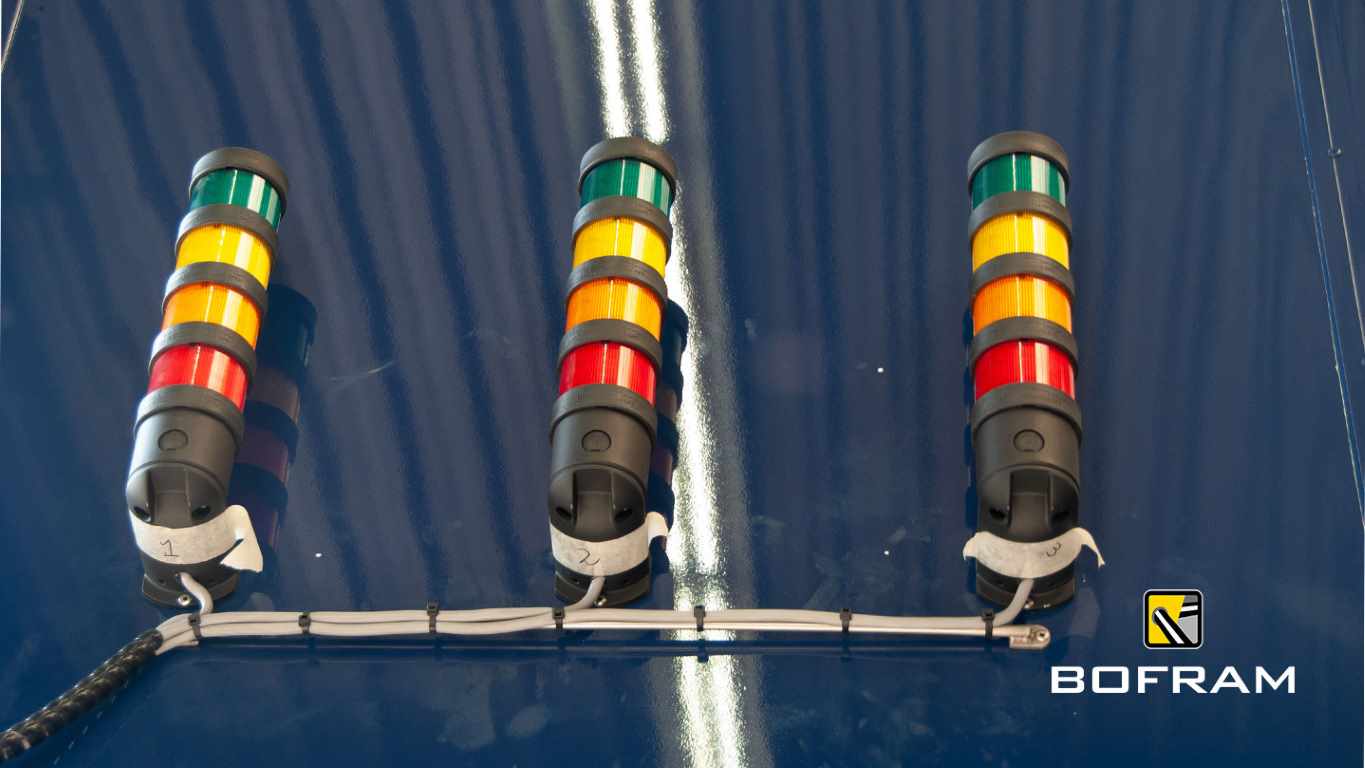

Between the tanks, a hopper table with an aluminum worktop is located. Above the hopper table are two power outlets and the control box to operate the mix pump set and the truck. The HDD system and the engine of the truck can also be operated by remote control.

We have equipped the truck with a 230 Volt installation with a 4000 Watt inverter that switches on automatically when the truck’s engine is running, as well as a shore power connection.

At the back of the truck, there is an extra workbench with four outlets and storage racks. Next to it, there is a hydraulic-driven reel with 50 meters of 1 1/4 ” hose with freewheel and safety. In the rear bumper is a water pump connection for automatic tank filling. The tanks contain a level measurement so that the system can automatically switch on when there is too little liquid in the tanks and automatically switch off when they are “full” again.

All this makes the drill truck so convenient to use. We wish 3D-Drilling a lot of enjoyable drill meters and thank you for the nice pictures from the drilling they executed close to Beverwijk.

Interested in a drilling truck like this?

Don’t hesitate to contact us if you are interested in a custom drilling truck.

Specifications HDD truck

| High pressure pump | FMC 260 L/min @ 70 Bar |

| Mix pump | Hydraulic driven mix pump with ceramic seal High mix speed |

| Electronics | Stainless steel control box with display and control buttons for: – Engine truck start/stop – High pressure pump on/off – High pressure pump liters +/- – Mix pump on/off – Clean water filling manual / auto – Clean water fill on/off – Display with pressure, litres and hours Remote control 230 Volt installation |

| Conservation | PE Pipework Steel piping blasted and powder coated |