Grouting unit, how does it work?

We often talk about horizontal directional drilling and the mix- & pump units you need to perform these. As Bofram Techniek, we engineer and realize these systems based on the client’s needs. There are various HDD systems. Our website shows that some systems only mix bentonite or grout, and some can mix & pump the drilling fluid. But how do these systems work in general? We will explain here how a grouting unit works.

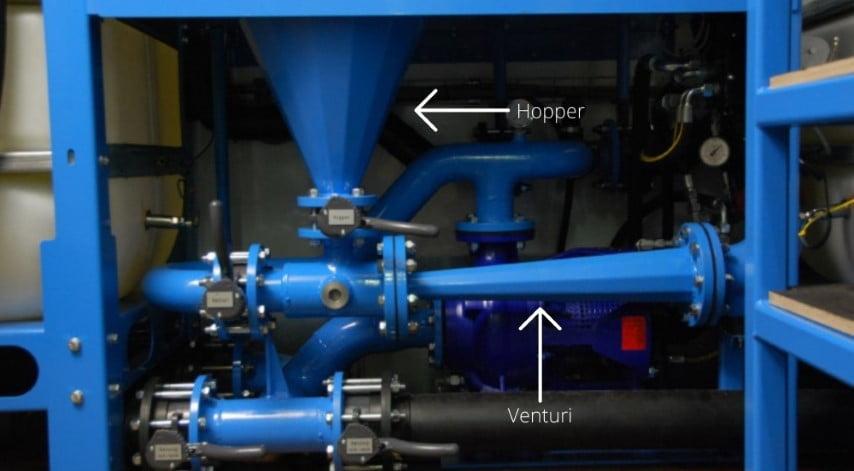

At the front of the machine, you can see a funnel. This is called the hopper. Grout, the dry product, will be thrown into this hopper, either by hand, with the use of a loader crane (Bigbag), or with the use of a suction pipe (Bigbag). Underneath the hopper table, you can find a butterfly valve and venturi which create an alteration in pressure from high to low. This in combination with the pump results in a water flow that sucks in the grout powder; the venturi effect. During this process, the grout powder breaks down in smaller pieces so it mixes better with water whenever it arrives in the mix tank through the eductor nozzles. The eductor nozzles ensure that the fluid is mixed continuously. Whenever the fluid is coming through the middle of the eductor nozzle, it also pulls fluid from the backside. If the fluid is coming through the ribs of the eductor nozzle, it helps to break down the particles a little bit more, just like the venturi. After a little while, you should check the viscosity. If it is too thick, you should add additional water. If it is too thin, you should add more drill grout. When the drill grout is just fine the pump may supply the drill rig and the horizontal drilling can start and/or the empty space created by the drilling can be filled.

Interested in the specifications of a grouting unit?

Have a look at the BFGMP 250 E.

Bofram is specialized in Bentonite and Grout pump units for directional drilling

The grout injection units developed and built by Bofram are 100% remote-controlled. The liters and working pressure can be read on the remote control.

Our total package is a super-advanced tool for HDD activities.

Advantages: fuel savings, bentonite/grout savings, time savings, easy error detection.

If you have any questions or comments regarding this article, please feel free to contact us. We are happy to help you.

Advice or questions about directional drilling?

Call for an appointment 0486-459045 or mail to info@bofram.nl