Electric mix container on hook lift hoist

Expansion of the HDD machine park

When you perform well and the demand for your horizontal directional drillings is growing, you sometimes need extra equipment. Hence, you need to think about renting an extra machine or invest in the expansion of your HDD machine park. After a period of renting, Moll Gestuurd Boren noticed that the demand for drilling continued to grow so they decided to expand their HDD machine fleet with a new custom-made mix container.

Electric mix container on a hook lift hoist

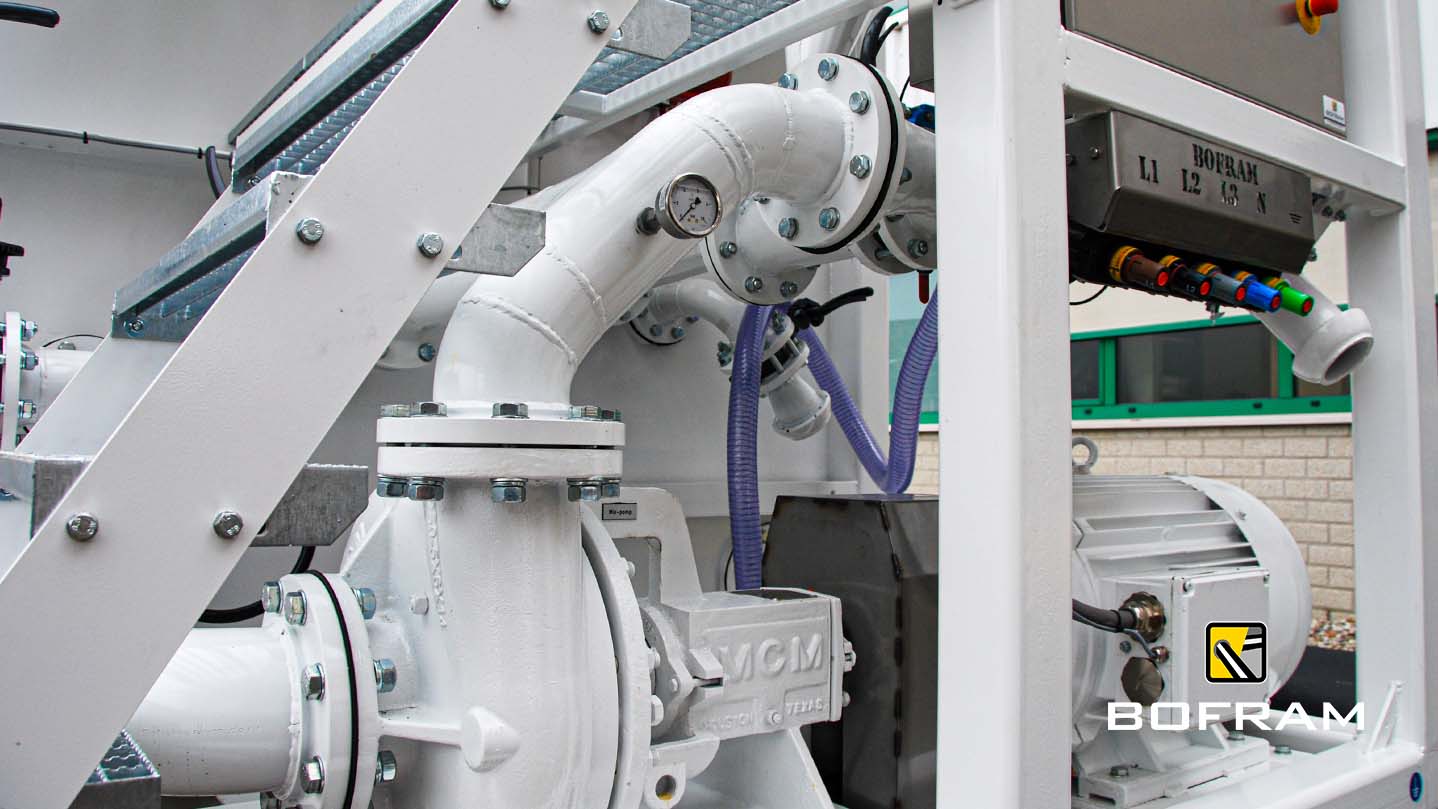

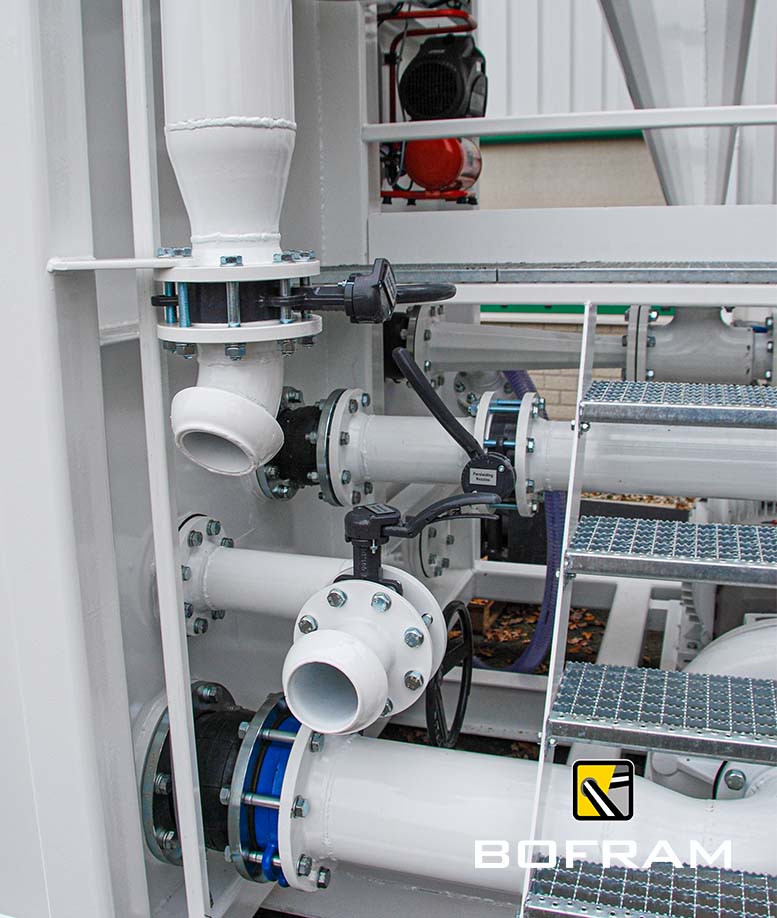

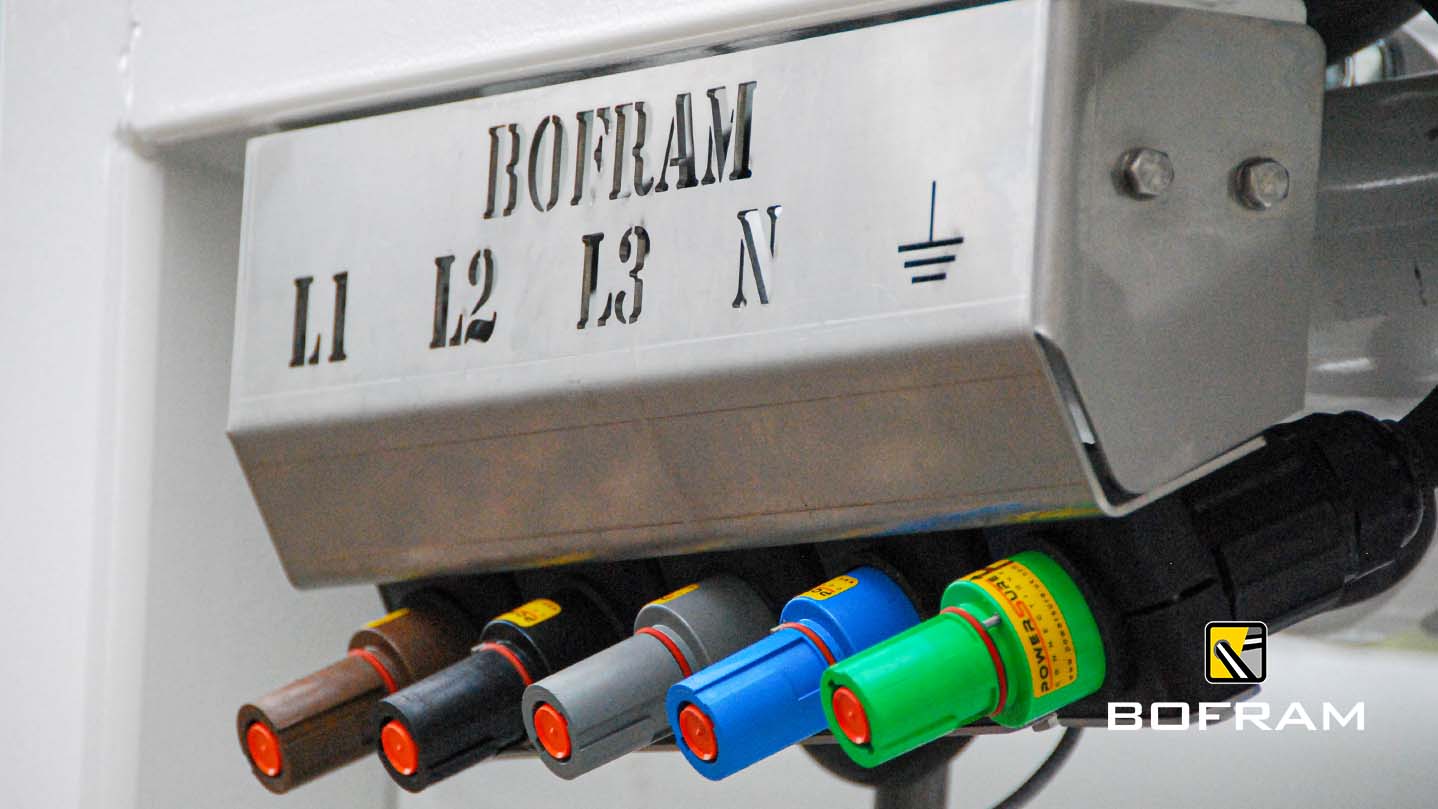

Moll Gestuurd Boren has chosen an electric mix container on an hook lift hoist. This way, the mix container can be pulled onto a truck for easy transportation. The steel construction of the mix unit has a sloping bottom, a lowered emptying point, and a lowered suction point for the pump. As such, the pump can draw more bentonite mixture from the tank without sucking in too much air. In addition, this is also useful for cleaning the mix container.

What stands out about the BFM2000E is the raised hopper table that is accessible via a fixed staircase. By placing the hopper table above the pumps, we keep the mix container as compact as possible and this allows the drilling engineer to have a good view of both the tank of the mix container and its surroundings. For an optimum ease of use, the stainless steel control box has extra buttons near the hopper table so the drillmaster can control the mix container from the platform.

To continue, we supplied two bigbag frames with this mix set. These can be placed on top of the hopper table so the crane can do other tasks. Furthermore, this mix container has the special Bofram venturi, various connections including a recycle mud connection, and a float level measurement.