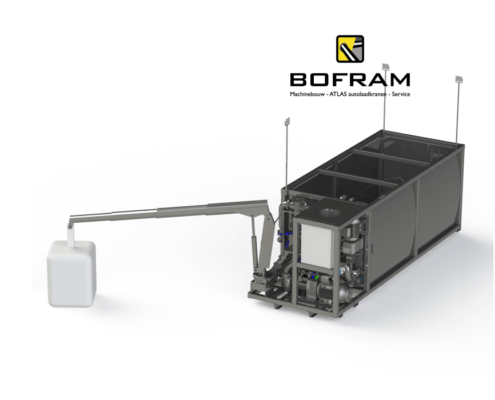

BFM 2000 EK

The loader crane is a very useful and ergonomic addition to the bentonite mixer. It consists of an electric mud and mix unit with an autoload crane for seamless drilling. This unit with a robust steel frame is built on a hook arm trailer. The mix unit is equipped with a crane that can be operated with a remote control. This crane can hang the big bag bentonite above the hopper table. Furthermore, the butterfly valves on the machine are easy to operate and the hopper table and associated tasks are easily accessible. Additionally, there is also a level measurement placed that is clearly visible to everyone. This mix installation is fully electrically driven and has a special fan with adapted piping and venturi. In this way, a high capacity is realized so that the mud masters can mix quickly.

Bentonite mixer with crane

BFM 2000 EK

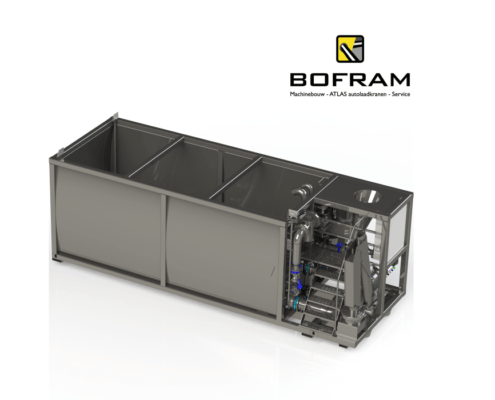

| Frame | Robust frame made of steel with hook lift system Steel and PE pipework |

| Dimensions | 7200 (L (mm)) X 2440 (W (mm)) x 2500 (H (mm)) |

| Mix pump power drive | Electrically driven, with soft starter |

| Mix pump | MCM short frame mix pump with mechanical seal Equipped with special impeller for faster maturation of bentonite |

| Mix capacity | 4500 liters per minute |

| Transferpump | MCM short frame mix pump with mechanical seal |

| Transfer capacity | 2500 liters per minute |

| Mix tank | Steel mixtank 25m3 with draining point and rounded walls. The tank is light in weight, is curved for minimal dirt accumulation and has lowered intake points for emptying the tank. Furthermore, the tank is equipped with a staircase, level measurement and recycling terminal. |

| Loader crane | Loader crane 5 ton/meter with a maximum reach of 5,1 meter. Electrically driven power pack |

| Control box | Stainless steel electrical control box mounted on unit ● Emergency stop, main switch, lighting on/off ● Mixing pump on/off ● Transfer pump on/off ● Loader crane on/off ● Hour meter ● Phase sequence monitoring ● Control lamps ● Display for status, faults, hours, maintenance intervals ● Activating button for bentonite suction from hopper table |

| Remote control | ● Wireless remote control ● Loader crane remote control |

| Additional | ● Position of filling line in consultation with customer ● Dirty water filter ● Hopper table with shut-off valve suitable for bigbag use ● Working lights x4 ● Blasting, scooping, 2K coating |

| Documentation | Documentation CE documentation Digital & Hardcopy Operating & Maintenance Manual in Dutch |